What Industries Benefit the Most From Air-Assisted Spray Systems?

Air-assisted spray systems are the preferred choice for automotive, wood, metal and industrial manufacturing. Compared to airless methods, these systems offer a high-quality finish with reduced overspray and material waste.

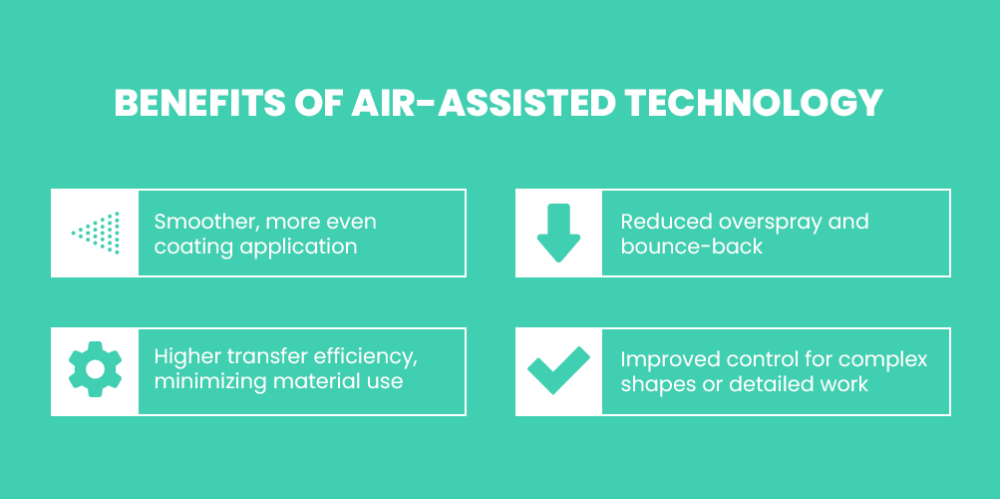

Benefits of Air-Assisted Technology

Air-assisted spray systems use compressed air to shape spray patterns, allowing for a softer spray with higher transfer efficiency. These spray systems offer several advantages:

- Smoother, more even coating application

- Reduced overspray and bounce-back

- Higher transfer efficiency, minimizing material use

- Improved control for complex shapes or detailed work

These systems mean fewer touch-ups and more material savings, too.

Industry Applications of Air-Assisted Spray Systems

Automotive Industry

In both manufacturing and refinishing, an air-assisted spray system for automotive companies allows for precise, even application of primers, basecoats and clearcoats. Compared to airless setups, air-assisted systems deliver better edge control and reduced rework.

Wood and Furniture Manufacturing

An air-assisted spray gun for furniture manufacturers can apply stains, sealers and lacquers with uniform coverage, even on ornate surfaces. The combination of a lower-pressure atomization and consistent fan patterns ensures a higher-quality finish when comparing it to an airless spray system.

Metal Fabrication and Finishing

For manufacturers working with steel, aluminum or other metals, an air-assisted spray system for metal can help ensure corrosion resistance and product longevity by allowing precise control over film build and adhesion. These systems are commonly used in the production of doors, equipment and structural components where precision coatings matter.

General Industrial and Aerospace Applications

Air-assisted spray systems are trusted for their balance of speed and control. Their versatility makes them suitable for applying everything from protective coatings to fine-finish topcoats, ensuring reliable performance.

Comparing Air-Assisted and Airless Spray Systems

What Can You Use an Airless Sprayer For?

Airless sprayers are ideal for high-volume projects. However, they lack the finesse and finish quality that air-assisted systems provide, making them less suitable when surface appearance is critical.

When Should You Choose Air-Assisted Over Airless Sprayers?

Air-assisted is the better choice when you're looking for controlled application, minimal overspray and a superior finish. It’s the best choice for detailed, high-value products.

Frequently Asked Questions About Air-Assisted Spray Systems

What Are Common Considerations for Manufacturers and Applicators?

When choosing a system, consider maintenance, tip selection and compatibility with your coatings. Air-assisted systems tend to integrate well into existing finishing lines.

How Do I Select the Right System for My Industry?

Choosing the correct system depends on your production goals. Consider material type, output level and finishing standards when choosing.

Explore Air-Assisted Spray Solutions With KM Coating

If finish quality and material savings are priorities for your business, upgrading to an air-assisted spray system may be the right move. KM Coating Inc. offers a full range of air-assisted spray solutions.

Contact us today for more information or to order your spray system.

Post comments

Leave A Reply

Your email address will not be published.